Inlet/exhaust port matching - worth it?

Inlet/exhaust port matching - worth it?

Hi everyone.

Im in the depths of the engine rebuild now.

The motor is in lots of bits, gearbox is out for rebuild and parts from the US have been ordered for the motor.

It would seem that my engine has seen some interesting times with what looks like a catastrophic failure (rod cap/bolt) of #8 at some point in its past, and the crank has had some serious work/machining done to resurrect it but unfortunately is past its best so a new 383 crank needed (luckily I have 2 spare!).

All the rods and rod end-caps are in the wrong order, with some stamped with numbers, some not but none of the marked ones in the right spot. It could be that the rods are from another engine/donor after the failure, but they will all be re-checked for ovality and marked to make 100% sure its as good as it can be on a budget.

Block will be chemi-dipped, re-bore to +040 (its +030 currently), new pistons, rings, bearings, cam, followers, chain, oil pump and a host of other things are coming soon so Im hopeful this will see the engine smoother and with a few of its lost horses returned.

Im not going for higher CP or fancy pistons or rings. I`ll leave the block deck as it is with just a clean up skim if needed.

Because everyone loves a picture or two:

Bare block - cam bearings still need to be knocked out and replaced Spare Crank (luckily I picked up a good one that has already been ground and polished to +010 locally). My question for today is port matching. Is it worth it, both in power/torque AND likelihood of over-doing it.

This is what I am faced with (inlet). A small amount of material removed at the corners will see the gasket match the head. If its worth doing, I`ll also be doing the same on the inlet manifold as well as some work on the exhaust side to make sure the exhaust manifold matches with the head.

Its not a large amount of 'meat' to remove, but nevertheless an opportunity to mess it up if Im not careful.

So whats the consensus on these engines? worth doing or lots of work for little to no gain?

Im not after a big HP engine, but if a few free horses can be gained for a bit of work then Im keen to hear about any tips/tricks.

Any suggestions?

Im in the depths of the engine rebuild now.

The motor is in lots of bits, gearbox is out for rebuild and parts from the US have been ordered for the motor.

It would seem that my engine has seen some interesting times with what looks like a catastrophic failure (rod cap/bolt) of #8 at some point in its past, and the crank has had some serious work/machining done to resurrect it but unfortunately is past its best so a new 383 crank needed (luckily I have 2 spare!).

All the rods and rod end-caps are in the wrong order, with some stamped with numbers, some not but none of the marked ones in the right spot. It could be that the rods are from another engine/donor after the failure, but they will all be re-checked for ovality and marked to make 100% sure its as good as it can be on a budget.

Block will be chemi-dipped, re-bore to +040 (its +030 currently), new pistons, rings, bearings, cam, followers, chain, oil pump and a host of other things are coming soon so Im hopeful this will see the engine smoother and with a few of its lost horses returned.

Im not going for higher CP or fancy pistons or rings. I`ll leave the block deck as it is with just a clean up skim if needed.

Because everyone loves a picture or two:

Bare block - cam bearings still need to be knocked out and replaced Spare Crank (luckily I picked up a good one that has already been ground and polished to +010 locally). My question for today is port matching. Is it worth it, both in power/torque AND likelihood of over-doing it.

This is what I am faced with (inlet). A small amount of material removed at the corners will see the gasket match the head. If its worth doing, I`ll also be doing the same on the inlet manifold as well as some work on the exhaust side to make sure the exhaust manifold matches with the head.

Its not a large amount of 'meat' to remove, but nevertheless an opportunity to mess it up if Im not careful.

So whats the consensus on these engines? worth doing or lots of work for little to no gain?

Im not after a big HP engine, but if a few free horses can be gained for a bit of work then Im keen to hear about any tips/tricks.

Any suggestions?

Andrew P

Perth, Western Australia.

Interceptor Mk3 #1284312

Perth, Western Australia.

Interceptor Mk3 #1284312

Re: Inlet/exhaust port matching - worth it?

Smoothing out those ports will not provide you any noticeable increase in horsepower, or a noticeable decrease in fuel consumption*.

All of these minor, incremental, changes/updates/improvements build upon each other to provide a more efficient engine, each providing a very small improvement.

The only reason to do it on your build (IMHO) is so that you know it’s done.

Doing so will give you some points in future bench racing contests.

Nevertheless if you don’t do it now, you will never do it. What’s another 6 to 8 hours into your engine at this point?

I vote YES!

Rocky

* That you can feel, because you can't do a "with / without" dyno test, to address Ray's point, below.

All of these minor, incremental, changes/updates/improvements build upon each other to provide a more efficient engine, each providing a very small improvement.

The only reason to do it on your build (IMHO) is so that you know it’s done.

Doing so will give you some points in future bench racing contests.

Nevertheless if you don’t do it now, you will never do it. What’s another 6 to 8 hours into your engine at this point?

I vote YES!

Rocky

* That you can feel, because you can't do a "with / without" dyno test, to address Ray's point, below.

Last edited by RockyUSA on Wed Aug 19, 2020 5:08 am, edited 2 times in total.

‘71 TVR Vixen 2500 - (M Series Tribute)

'72 Interceptor III - 133/5597

'73 DeTomaso Pantera

'74 Toyota Land Cruiser FJ-40

'95 Jaguar XJS Convertible

'72 Interceptor III - 133/5597

'73 DeTomaso Pantera

'74 Toyota Land Cruiser FJ-40

'95 Jaguar XJS Convertible

Re: Inlet/exhaust port matching - worth it?

Agree with Rocky, WILL be better and personally I think you would quite easily find the difference on the dyno.

However I do think 6 to 8 hours is a bit optimistic!!

The one item to be careful with is to understand exactly where the inlet and exhaust manifolds are when bolted down, the gasket is not a good enough reference. There are plenty of good youtube videos on how to match/mark the parts. In my case the exhaust alignment was fair but the intake (Edelbrock Performer) was awful and the attachment holes had to be modified and then carefully assembled with guide marks to get good port match.

As Rocky says - this is your one opportunity.

However I do think 6 to 8 hours is a bit optimistic!!

The one item to be careful with is to understand exactly where the inlet and exhaust manifolds are when bolted down, the gasket is not a good enough reference. There are plenty of good youtube videos on how to match/mark the parts. In my case the exhaust alignment was fair but the intake (Edelbrock Performer) was awful and the attachment holes had to be modified and then carefully assembled with guide marks to get good port match.

As Rocky says - this is your one opportunity.

MkIII Interceptor (140 8488)

Re: Inlet/exhaust port matching - worth it?

Pocket porting is well and truly worth the effort, but port matching commonly yields little to no improvement.

1964 Jensen CV-8 II

Re: Inlet/exhaust port matching - worth it?

Agree the pocket porting is at another level, a seat of the pants benefit when I had mine done.

I think the matching benefit would depend on how bad it is, there must be a point where mismatches will reduce flow capacity which of course depends on the application. I did a dyno exercise some years ago using special adapters creating different types and size of mismatch on a VW engine, the conclusion was that zero mismatch was the best solution but only by a small amount.

I think the matching benefit would depend on how bad it is, there must be a point where mismatches will reduce flow capacity which of course depends on the application. I did a dyno exercise some years ago using special adapters creating different types and size of mismatch on a VW engine, the conclusion was that zero mismatch was the best solution but only by a small amount.

MkIII Interceptor (140 8488)

Re: Inlet/exhaust port matching - worth it?

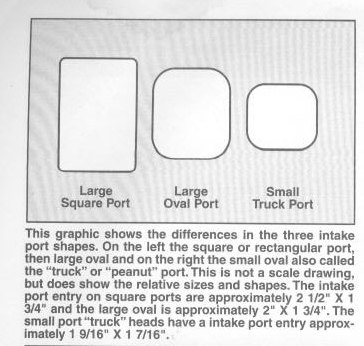

An extreme example of how port mismatches may not make much of a difference relates to the Big Block Chevrolet (BBC). A square port inlet manifold has been proven to work very well on an oval port head. See the image to get an idea of the degree of port mismatch.

1964 Jensen CV-8 II

- Steve Payne

- MASSIVE RED CARD

- Posts: 6467

- Joined: Thu Nov 17, 2005 4:51 pm

- Location: Witney , Oxfordshire

- Contact:

Re: Inlet/exhaust port matching - worth it?

You used to be able too buy some templates for the ideal port shape. Some one I know bought a set of heads that had already been ported and he reckoned the engine was a lot more free revving.

If you are after a little more efficiency from your engine getting the compression close to 10 to 1 is a good idea.

Steve

If you are after a little more efficiency from your engine getting the compression close to 10 to 1 is a good idea.

Steve

JOC official Lightning engineer

Re: Inlet/exhaust port matching - worth it?

Here are the porting templates.Steve Payne wrote:You used to be able too buy some templates for the ideal port shape. Some one I know bought a set of heads that had already been ported and he reckoned the engine was a lot more free revving.

If you are after a little more efficiency from your engine getting the compression close to 10 to 1 is a good idea.

Steve

https://www.bigblockmopar.nl/wp-content ... Magnum.pdf" onclick="window.open(this.href);return false;

1964 Jensen CV-8 II

Re: Inlet/exhaust port matching - worth it?

If you are going to skim the block to square it up, then you might as well ensure that the quench height is optimised.

- It will increase the compression ratio which will help with energy efficiency and power as well as giving you more options when it comes to camshaft selection

- It will improve quench and hence detonation resistance.

The right quench height can be achieved by balancing the deck height of the block, compression height of the pistons and the gasket thickness.

- It will increase the compression ratio which will help with energy efficiency and power as well as giving you more options when it comes to camshaft selection

- It will improve quench and hence detonation resistance.

The right quench height can be achieved by balancing the deck height of the block, compression height of the pistons and the gasket thickness.

1964 Jensen CV-8 II

Re: Inlet/exhaust port matching - worth it?

What do you think an optimum quench height is? I’m nearly ready to press the go button on my 383 rebuild - 438 stroker with the original 906 heads. The 440Source pistons have a compression height of 1.320”. My block has not been decked as far as we can tell (stock pistons are within 0.005” of the deck at TDC which is very close to the factory 0.005-0.006” proud deck clearance for a 1969 383). With a rod length of 6.760” and 438 stroker stroke of 3.750”, and a 0.019” steel shim gasket (to a achieve a static CR of 9.6:1) the quench height should be:

9.980” deck height less 6.760” less 3.750”/2 less 1.320” = 0.025” deck clearance plus 0.019” = 0.044” quench height

Thoughts?

9.980” deck height less 6.760” less 3.750”/2 less 1.320” = 0.025” deck clearance plus 0.019” = 0.044” quench height

Thoughts?

Nigel Kieser

Bradford on Avon, Wiltshire

Interceptor 115/3484

Bradford on Avon, Wiltshire

Interceptor 115/3484

Re: Inlet/exhaust port matching - worth it?

I'd say 0.040" to 0.045" is a good range for quench height.

1964 Jensen CV-8 II

Re: Inlet/exhaust port matching - worth it?

I hadn’t come across the term “quench” so looked it up and thought others in my position may find it useful. Interesting that they make reference to the 1970’s 440’s indicating how bad they are based on current thinking.

https://www.hotrod.com/articles/ideal-quench-height/" onclick="window.open(this.href);return false;

Hopefully this link work.

https://www.hotrod.com/articles/ideal-quench-height/" onclick="window.open(this.href);return false;

Hopefully this link work.

Adrian

1974 Interceptor Mk III 2240-9415

JOC Member 9648

1974 Interceptor Mk III 2240-9415

JOC Member 9648

- Steve Payne

- MASSIVE RED CARD

- Posts: 6467

- Joined: Thu Nov 17, 2005 4:51 pm

- Location: Witney , Oxfordshire

- Contact:

Re: Inlet/exhaust port matching - worth it?

If you were to use Edelbrock heads they have a squish of 38thou or more precisely the thickness of the head gasket they recommend you use if your pistons go to the top of the bores.

Steve

Steve

JOC official Lightning engineer

Re: Inlet/exhaust port matching - worth it?

Probably the most common gasket compressed thickness would be 0.040". So it is straight forward to go with zero deck height (pistons flush with deck) and 0.040" head gaskets, which gives a good quench height of 0.040". You could use the same approach with any gasket between 0.039 to 0.045" and get a good result.

1964 Jensen CV-8 II

Re: Inlet/exhaust port matching - worth it?

And here is one we prepared Earlier just for this thread  .. Edelbrock heads with "0" Deck Height with 10.5:1 compression,

.. Edelbrock heads with "0" Deck Height with 10.5:1 compression, .

.

The block and deck faces have been squared with the bores, this insures that all compression ratio's are the same from back to front, this is something that alot of Mopars when checked have intolerance's

The block and deck faces have been squared with the bores, this insures that all compression ratio's are the same from back to front, this is something that alot of Mopars when checked have intolerance's

Manual Int&Rag-Top

"Monkey Man"sig Registrar

"Monkey Man"sig Registrar